COMMERCIAL LEAKS

Leak correlators are an efficient and effective way to locate leaks in commercial, industrial, and civil water services, and trunk main applications. They are used where the rough location of the leak is unknown and the distances relatively high.

How does it work?

A leak noise correlator is an electronic device used for detection of leaks in pressurized water or gas lines. Typically, microphones or acoustic sound sensors are placed in contact with the pipe, at two or more points, to record the sound emitted by a leak somewhere between the points. The sound data is processed through a mathematical algorithm which compares or correlates the two recordings to determine the difference in the times it takes noise to travel from the site of the leak to each of the sensors. If the distance between the sensors is known in advance, this timing information can be used to determine the location of the leak.

In the correlation process, two sensors are deployed on pipe fittings positioned either side of the suspected leak location. Noise is created by the leak as it escapes from the pipe under pressure. This noise is conducted in both directions away from the leak through the pipe wall as minute vibrations, and through the water column as a pressure wave.

In the correlation process, two sensors are deployed on pipe fittings positioned either side of the suspected leak location. Noise is created by the leak as it escapes from the pipe under pressure. This noise is conducted in both directions away from the leak through the pipe wall as minute vibrations, and through the water column as a pressure wave.

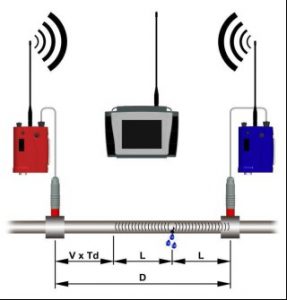

The leak noise travels at a constant velocity (V) which depends on the material and diameter of the pipe and arrives first at the sensor nearest the leak. The arrival time at each sensor is registered. The time difference (Td) between the two arrival times, combined with knowledge of the sound velocity, which is provided by the pipe type and length, allows the leak position to be calculated by the correlator. Depending on the environmental conditions, accuracy of leak pinpointing can be within centimetres. The principle of correlation can be defined by: L = ½ (D-(VxTd)) and is shown here graphically.

Priority Plumbing’s correlator system has class leading accelerometers (sensors), filter optimisation (automatic noise filter setting and frequency selection) and is setup for all pipe types and sizes that we use in Australia including Cast, Asbestos, PVC, HDPE, and Copper.

These images show the deployment of the two sensors either side of the suspected leak. One on the fire hydrant and one on the isolation valve upstream. The correlator then calculates the position of the leak. This is effective for distances of up to 400m.